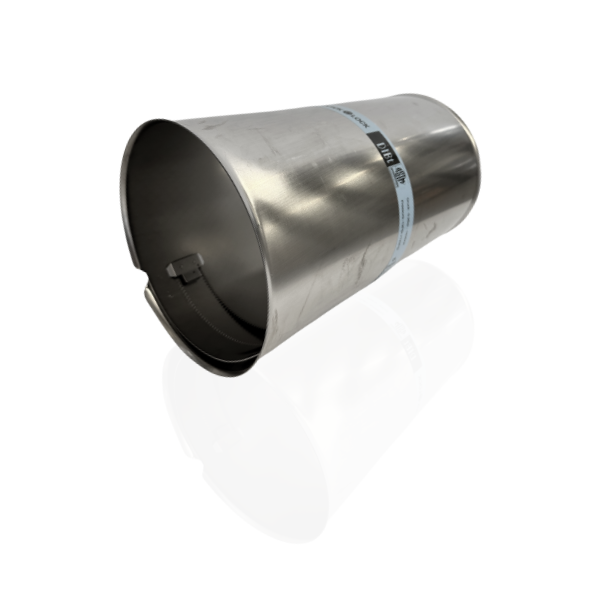

Quick-Lock PRESSURE PIPE LinerEnd (LD + HD)

The system for Liner connection in pressurized pipelines

Application: pressurized pipelines

- Liner connection

The Quick-Lock PRESSURE PIPE LinerEnd sleeve (LD+HD) was developed for liner connection with a nominal diameter of DN 150–800 / 6″–32” and internal pressures of -0.9 bar to +50 bar / -13.05 psi to +725 psi. LD stands for “low duty” and HD means “high duty”.

Quick-Lock PRESSURE PIPE LinerEnd (LD+HD) system description

The Quick-Lock PRESSURE PIPE LinerEnd sleeve (LD+HD) serves to liner connection with a nominal diameter between DN 150 and DN 600 / 6” and 24”. The Quick-Lock PRESSURE PIPE LinerEnd sleeve (LD) was designed to rehabilitate pressurized pipelines that are subject to infrequent, low-intensity pressure surges.

It is suitable for static internal pressures from -0.9 bar to +50 bar / -13.05 psi to +725 psi and for dynamic internal pressures from -0.4 bar to + 3 bar / -5.80 psi to +43.51 psi.

The Quick-Lock PRESSURE PIPE sleeve (HD) was developed to permanently withstand high-frequency, high-intensity pressure surges. In the course of testing, the sleeve was able to endure more than 2 million pressure load cycles between -0.9 bar and +50 bar / -13.05 psi and +725 psi, thanks to its advanced locking mechanism, thicker material, and special alloy. The allowable dynamic internal pressure in from -0.9 bar to +10 bar / -13.05 psi to +145.04 psi.

This is a milestone never before reached in the sleeve technology sector.

When using a Quick-Lock LinerEnd sleeve in a pressurized pipeline, the pressure resistance can only be guaranteed when the sleeve is used in combination with a protector shield.

The protector shield stops the seal from creeping into any gaps or cracks in the pipe wall. This prevents the seal from being damaged.

How it works

- The Quick-Lock PRESSURE PIPE LinerEnd sleeve (LD+HD) was developed specifically for use in pressurized pipelines.

- For internal pressures from -0.9 bar to +50 bar / -13.05 psi to +725 psi.

- The Quick-Lock PRESSURE PIPE LinerEnd sleeve (LD) was designed for Liner connections in pressurized pipelines that are subject to infrequent, low-intensity pressure surges.

- The Quick-Lock PRESSURE PIPE LinerEnd sleeve (HD) was developed to ensure long-term resistance in the case of high-frequency, high-intensity pressure surges.

- The Quick-Lock PRESSURE PIPE sleeve is also available as a STANDARD sleeve (LD+HD).

What you need

- Camera or robot system

- Compressor

- Quick-Lock installation packer

Advantages of the system

- Purely mechanical clamping

- User-friendly

- No chemical construction materials

- Long service life

- Refined locking mechanism

- Special alloy

Scope of application

- Sewer pipes

- Potable water pipes

- Seawater pipes

- Industrial pipes

- Pressure pipes

- District heating pipes

- Pipelines

Specifications

Materials

The materials 316L /904L stainless steel and the silicone seal are used in potable water applications, seawater areas, wastewater pressure pipes, industrial rehabilitation, and for sealing boreholes or district heating pipelines.

The stainless steel grades 316L / 904L are virtually indefinitely durable.

For rehabilitation in seawater areas stainless steel grade 904L is used.

Product range

Two different sizes of Quick-Lock PRESSURE PIPE LinerEnd sleeves (LD+HD) are available:

- Type 1: Length 250mm/9.84”; suitable for diameters DN 150–400 / 6"–16”, LD + HD= internal pressures between -0.9 bar and +50 bar / -13.05 psi to +725 psi

- Type 2: Length 300mm/11.81”; suitable for diameters DN 450–800 / 18"–32”, LD + HD= internal pressures between -0.9 bar and +50 bar / -13.05 psi to +725 psi

Quality and certifications

All information (data sheets, instructions, and approvals) for the entire Quick-Lock system from UHRIG as well as order forms can be found at: Downloads: Downloads

If you’d like to know more about our products, we’re happy to answer your questions anytime.